Technology | Suspension | Tires and spikes |

Riding gear

Years ago some winning bikes was equipped with road-racing engines,

usually in moto-cross frames. But some successful curiosities have been

seen, like Triumph Tiger Cup 200cc mod. 1952 frame with 19” front wheel

and 17” rear, engine Yamaha AS-125 Twin with road-racing kit. Vehicle

weighted about 75kg and was capable to over 140 km/h. (Early 70:ies).

Interestingly those bikes not so successful in  moto-cross

have been winning models on ice, like Bultaco Pursang 250 and even Bandito

360cc, Suzuki TM400, KTM500, Rotax engines (LC128, LC129,LC257) in MX-bike

frames and so on. Engine power counts with high speed maneuverability.

Nowadays sophisticatedly tuned MX singles and carefully modified suspension

do the work when counted moto-cross

have been winning models on ice, like Bultaco Pursang 250 and even Bandito

360cc, Suzuki TM400, KTM500, Rotax engines (LC128, LC129,LC257) in MX-bike

frames and so on. Engine power counts with high speed maneuverability.

Nowadays sophisticatedly tuned MX singles and carefully modified suspension

do the work when counted

as lap times. Commonly seen cases and even cylinders welded , reshaped

channels and re-plated for better gas flow. Computer adjusted ignitions

is a must, with several feedbacks from engine and carburettor.

Think about Honda CR 125 ported to RS cylinder specs and TPS + PJV controlling

ignition box, pipe compromise between RS and CR, secondary gearing 13/39.

It does 145 km/h with heavy rolling spiked tires on ice just before

diving into fullspeed lefthander. If not enough, do it with high tuned KTM 525 SX ,

speed 175km/h, in slight slide, among with fifteen competitors, icescrabs

hitting your body… that´s iceracing!

|

Suspension

Spring

rates should be softer than used in cross. Front end is lowered about

60 mm and rear in balance. Best method for rear end is to make “chikenleg”

–levers about 7mm longer for those bikes having such. It will change

the progressivity curve better for track purposes and lower height.

Different methods can be done to prevent “loose rising” in acceleration

or braking. Spring

rates should be softer than used in cross. Front end is lowered about

60 mm and rear in balance. Best method for rear end is to make “chikenleg”

–levers about 7mm longer for those bikes having such. It will change

the progressivity curve better for track purposes and lower height.

Different methods can be done to prevent “loose rising” in acceleration

or braking.

Gearing

General rule: So tall that bike has no more power to overrev with tallest

gear. It means about 13/40 in most bikes. Enduro like; "Wide ratio"-

gearboxes is definently not good for serious racing.The gap between

the gears, especially fourth and fifth, is too big.

|

Tyres and spikes

Driving on ice with no-spiked tires looks comical.

But how to get something logical to gravel or asphalt grip on ice – that´s

not an easy task.

In Finland, it was 1966 when first time spikes were allowed. Since then

we have had several regulations, such as uttermost through screwed

caulks or as opposite “normal” car studs. Now our regulations for spikes

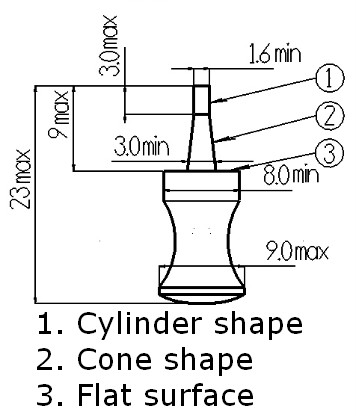

are as you can see from the drawing.  Spike

material is normal construction steel (Fe52), which is easy to machine.

And it does react to heat treating (gas carbonizing) to get very thin

(app. 0.1 mm) hardened surface. It is necessary to keep edges sharp

and especially it makes the thin tip stronger. Spike

material is normal construction steel (Fe52), which is easy to machine.

And it does react to heat treating (gas carbonizing) to get very thin

(app. 0.1 mm) hardened surface. It is necessary to keep edges sharp

and especially it makes the thin tip stronger.

The requirements concerning the tire carcass is that you must be able

to drill a 14,5 millimeters deep hole in to the knob. It's not recommended

that the hole goes through the tire. We mostly use at rear HWA Fong

type HF-311, or similar HF Duro, sizes 3.50-18 or 19. Most of common

"semi-enduro" tires e.g. Michelin T63 or some types of Metzeler

will also do well. Motocross tyres are usually too hard (the knobbies tear

off) and the pattern is too wide. Up front any of Metzeler MC E/4/5/6

Cross 21" or Duro types.

Typical amounts of studs: Due to our regulations it is allowed to put

60 studs/along surface length of 300mm, on the rear tire. On HWA Fong

type HF-311, or similar HF Duro, 45 studs/300mm. This means total amount

of ~350 studs. On the front wheel; there is no limit. Total amount

of ~350 pcs will do well.

About the spike gun: Those we use are airpressure powered, accepting

stud diam. min 9mm. Very similar to the ones used for car tire studding

here in Finland, but designed for heavier use. The aircompressor must

produce at least 8 bars of pressure.

The drill: Also powered with compressed air, revs: 8000 - 14000/minute.

Bit diameter 4mm, must be designed to drill rubber because it is very

critical that the hole is clean, cylindrical and of correct depht.

The

glue: We have tested many types of glues and the best is Loctite 496

cyanoacrylate glue. It should be globally available. The glueing process

itself is more or less interesting; First; The amount of glue should

be correct (fill 1/3 part of the hole) because too much of it will splash

the glue around when the stud is shot in. That will seize the spikegun

because the cyanoacrylate is hardening fast. Second; Remember ALWAYS

to use SAFETY GOGGLES!! It is easiest to insert the glue with a injection

needle used for medical purposes. The

glue: We have tested many types of glues and the best is Loctite 496

cyanoacrylate glue. It should be globally available. The glueing process

itself is more or less interesting; First; The amount of glue should

be correct (fill 1/3 part of the hole) because too much of it will splash

the glue around when the stud is shot in. That will seize the spikegun

because the cyanoacrylate is hardening fast. Second; Remember ALWAYS

to use SAFETY GOGGLES!! It is easiest to insert the glue with a injection

needle used for medical purposes.

First of all: The studs must be treated with HCL (hydrochloric acid);

drown the studs to the acid in a plastic can, keep them there for max.10

minutes, then rapidly flush them with plenty of hot water. Then dry

the studs with hot or compressed air. The goal is to make the surface

extremely clean and slightly coarse. The studs must not be rusty, though.

Studding tires is work of art with many phases, it takes patienced and

careful work to achieve the ideal results. In Finland, our top manufacturers

have done this for over 20 years, and their equipment/tools are of top

level.

|

Riding gear

Racing

conditions may vary from freezing point to extremely cold weather. Usually

the temperature is around -5 Celsius to -15 Celsius, but a race at -25C

has been experienced! This may sound horrible, but the truth is that

its not. The new materials such as, kevlar, goretex, ... are good enough

to keep you sweat! It is very important to prevent wind from blowing

to bared skin. Critical points are neck, wrists, knees. How about the

nose? And the rest of the face?..... Not a bad choice is a helmet designed

for snowmobile use.The ventilation, double visor and strap is especially

designed for cold conditions. Racing

conditions may vary from freezing point to extremely cold weather. Usually

the temperature is around -5 Celsius to -15 Celsius, but a race at -25C

has been experienced! This may sound horrible, but the truth is that

its not. The new materials such as, kevlar, goretex, ... are good enough

to keep you sweat! It is very important to prevent wind from blowing

to bared skin. Critical points are neck, wrists, knees. How about the

nose? And the rest of the face?..... Not a bad choice is a helmet designed

for snowmobile use.The ventilation, double visor and strap is especially

designed for cold conditions.

|